Transform Your Outdoor Space with Decko Deck Tiles.

Discover the simplicity of transforming your outdoor spaces with our comprehensive guide to installing Decko deck tiles. Perfect for beginners and DIY enthusiasts alike.

Transform Your Outdoor Space with Decko Deck Tiles.

Discover the simplicity of transforming your outdoor spaces with our comprehensive guide to installing Decko deck tiles. Perfect for beginners and DIY enthusiasts alike.

Recommended Tools:

- Drill/screwdriver with Phillips head

- Angle Grinder with cutting wheel/hack saw/cide cutters

- Polyeuthane Based Glue / Liquid Nails

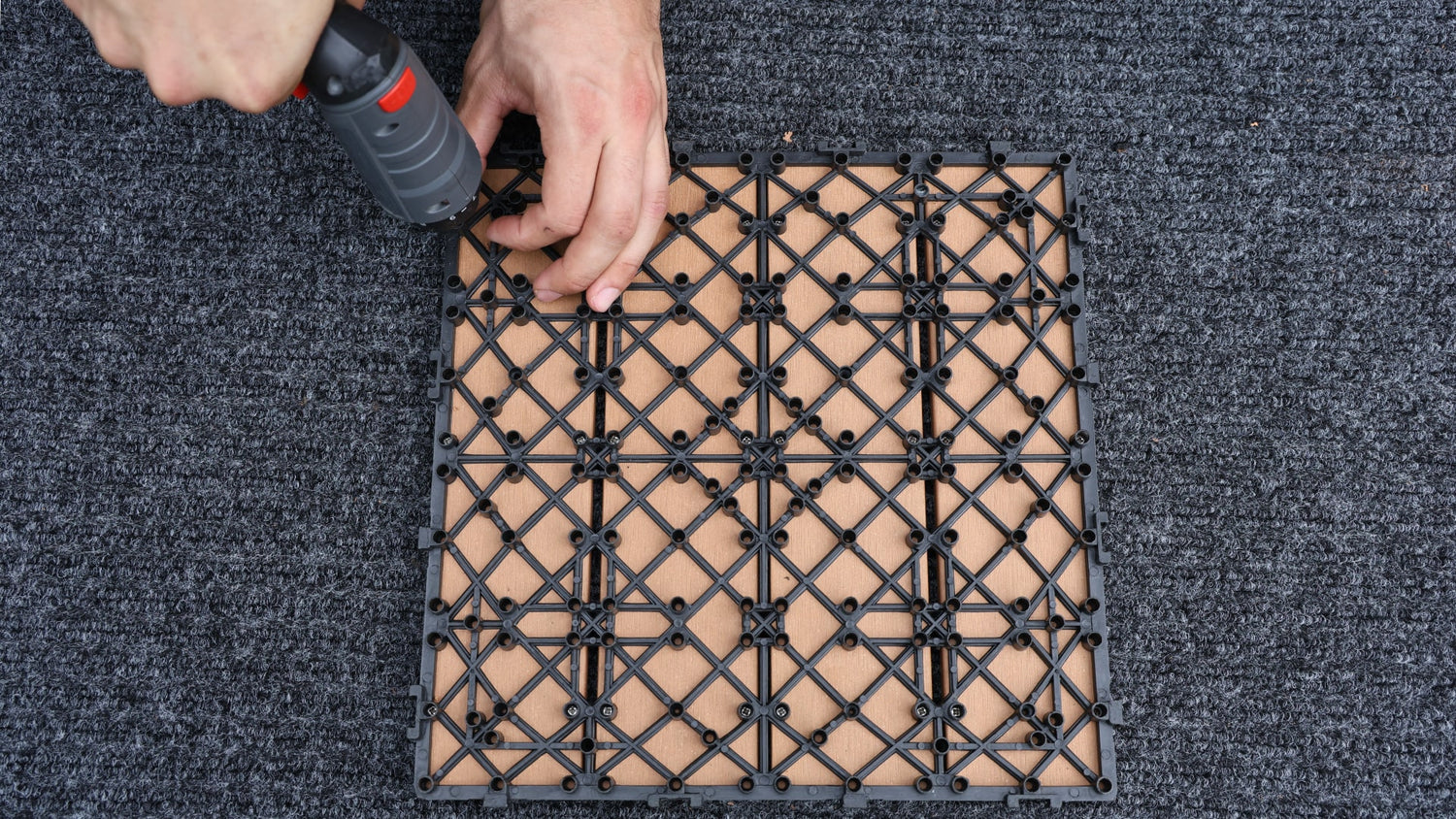

Locate the three screws at the very edge of the Decking tile. Using the appropriate screwdriver or a drill with the right bit, carefully remove these screws. This step is essential for preparing the tile for a custom fit on your steps.

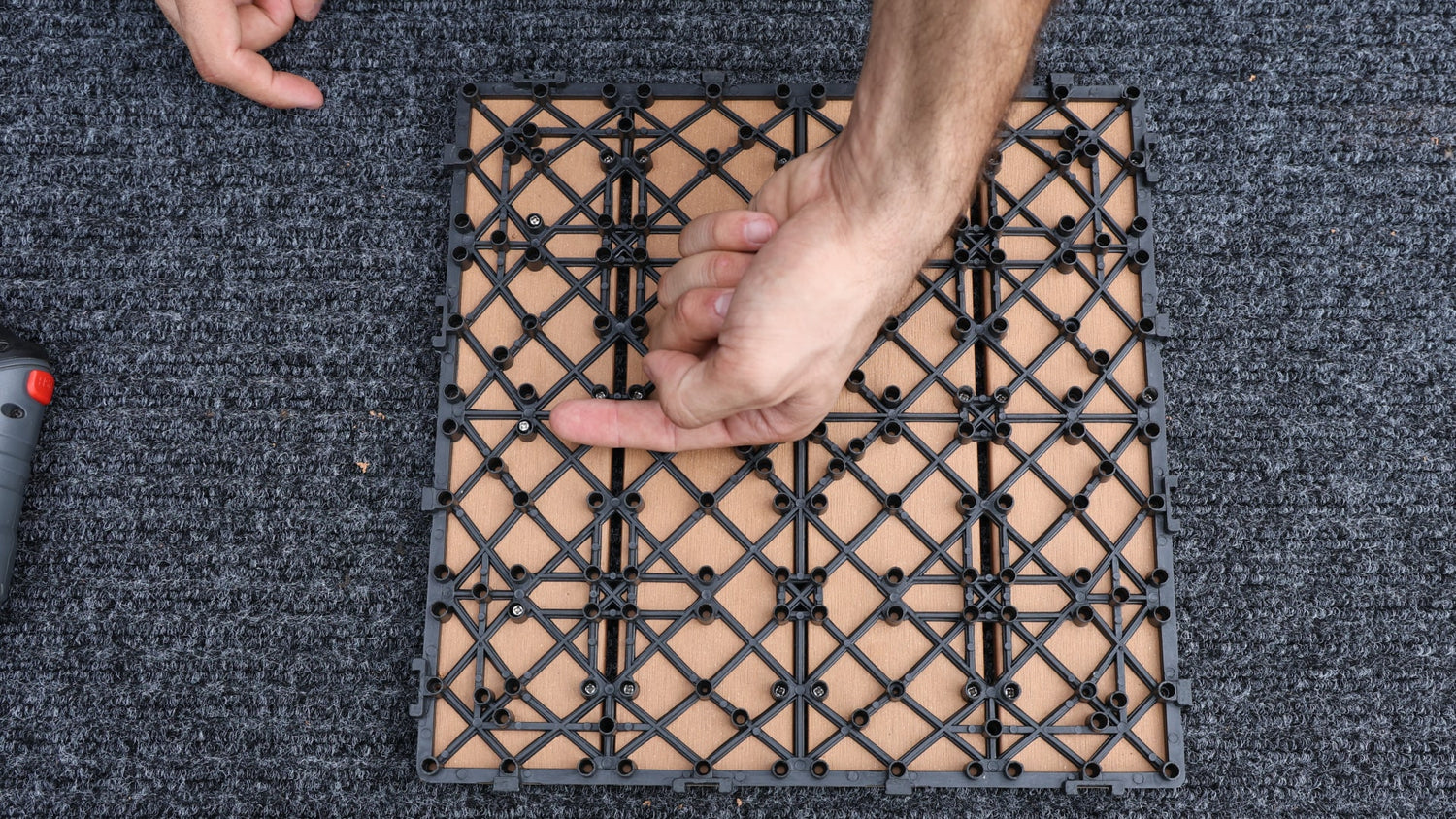

Once the screws are removed, you will reposition them. Place the screws back into the tile but further inside, ensuring they are evenly distributed. This repositioning helps in securing the tile firmly while accommodating the step's edge.

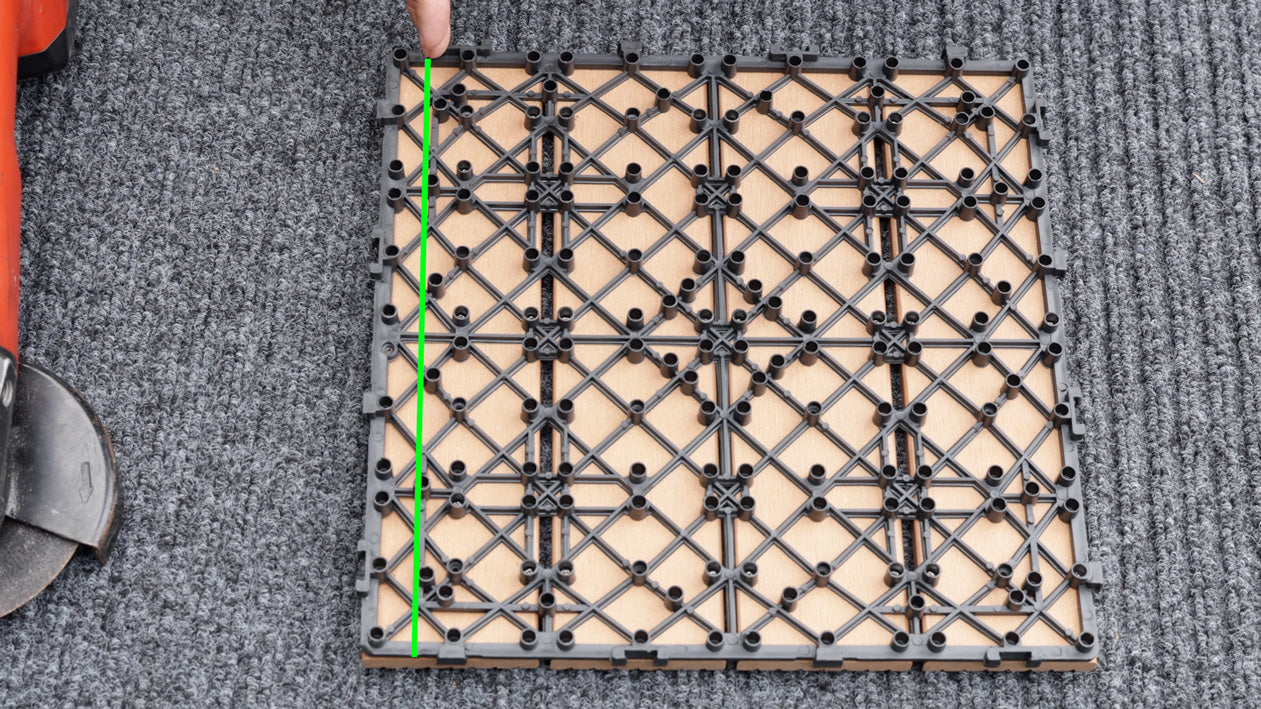

To fit the tile onto the step perfectly, you might need to trim or adjust the edge of the tile. Depending on the tool you have, you can use a hack saw, a grinder with a cutting wheel, or side cutters for this task. If using a grinder, ensure it’s equipped with a cutting wheel suitable for the material of your Decking tile.

Carefully cut along the base mesh ensuring you don't cut into in the tile.

Apply a polyurethane-based glue to the bottom of the tile that will be placed vertically. Ensure that that you place large dots of glue across the tile, like in the image. After preparing the edge and applying the adhesive, carefully place the tile on the step. Ensure it is aligned properly before pressing down firmly. Allow the adhesive to cure as per the manufacturer's instructions before stepping on it or applying weight.

If you wish to match the edge of the tile to the rest of its brushed finish, sanding is required. Use 60 grit sandpaper to sand down the edges or any part of the tile you adjusted. This will help in blending the modification seamlessly with the rest of the tile's surface.